So I bought a micro swiss direct extruder kit for CR10/Ender3 with all metal hotend for my Anet ET5pro and encountered several problems:

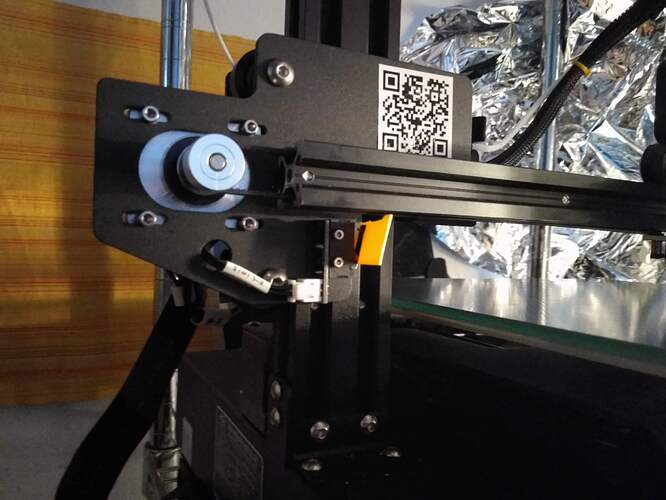

First, the extruder carrier hit the QR code thing, so the carrier must be distanced with in my case 4x 1mm thick o-rings at each wheel. (See pic in attachments.)

Then the extruder carrier missed the x endstop, crashing, so I had to glue the yellow piece of plastic (with contact glue) to the endstop to make it work again, see pic.

Then I had to solder the extruder motor cable 180° turned around to make it extrude in the correct direction, which was not really bothering, as the cable is neatly at lenght now.

The Anet filament sensor must be reused, leave it in place together with the now motorless feeding bracket. The old press fit attachment for the bowden tube holds stirdier, don’t use the furnished micro swiss red-one, see pic.

Adapt the Cura extruder setting to 1,5mm retraction.

Now, it prints, but in the air: z axis software endstop.

So I added some o-rings to raise the tension of the springs, pushing the print bed further up. Not enough, see pics.

I lost about 1" in the y axis and - still have to check - some mm in the z axis.

And the ventilator casing holds now with only 1 screw, a fitting replacemt will be printed later.

As I bought the printer with Marlin installed, I hesitate to flash Marlin from scratch.

Would someone have the Anet ET5pro Marlin configuration file for easy compiling, wouldn’t you?

Or explain the M 206 and M 428 thing for slow ?, so that the final values saving M500 works?

Thanks for your practical support.