I have been busy playing with my new etching machine. I thought I would share some information and some pictures.

First off, with these machines you have to have a computer running a program called Lightburn. ( https://lightburnsoftware.com/ )

This one is not free, it costs about $60 US. I watched early on when I was playing with the LaserPecker all these ways to get a picture in lightburn – But lightburn it’s self can do all the stuff except split the picture into multiple sections to print on, for example ceramic tiles. It is an internet program, you cant own it just use it on the internet. I like the idea of doing this to get large pictures. You can do it with any picture for any reason.

Lightburn can edit pictures. It can create pictures like illustrator or coral draw. In short I am really impressed with this program. When you are through editing the file you want to send to the etcher, it then acts like marlin. You can, if you want see the gcode it is sending.

Lightburn even incorporates cameras. I have watched a couple of videos on Lightburn being used with cameras. That is the most impressive part of lightburns capabilities. ( LightBurn Camera Demo - YouTube )

LaserGBRL is a free piece of software that is available to to connect to a laser etcher. This software is the one all the earlier videos I watched having you go through a dozen different internet programs to get your file ready to etch. ( https://lasergrbl.com/ )

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“small”,“data-attachmentid”:14662}[/ATTACH]

This is the finished product (temporary) I have set up to use the Atomstack. This is wherte I had my Geeetech. You see the little red 3dprints at the feet. I printed them to make the etcher stable on the board. It sticks out over the counter. The mess in the middle is a template to place 6 small cards of cardboard, plywood, or basswood. Even other materials that size. From what I see and read you need to make a template for any printing. The camera would solve that part. The camera from where you place it shows the flattened bed and all you do is place the piece or pieces on the bed and lightburn identifies them and then you place your etchings files on them. No templates needed. Grand Idea I will spend money on next.

The mess in the middle. Right now it serves another function also. The laser I have is a fixed focus (safest way), and it will not lower to the bottom board. I have a honeycomb plate ordered to solve that problem but it will not arrive until April 22.

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“medium”,“data-attachmentid”:14663}[/ATTACH]

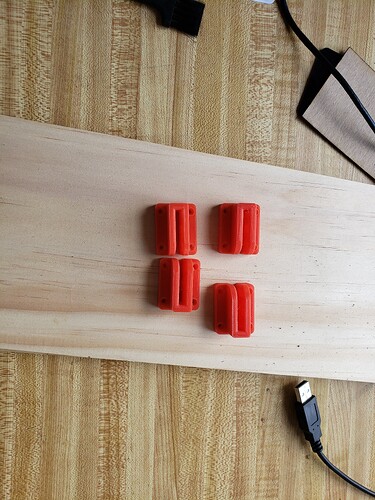

These are the 4 lock feet I printed on my Artist-D I had to get some screw but now I cannot accidentally move the etcher unless I move the hole board and it is butted against a laser printer and the back of the counter.

The board is 5/8 plywood cut to be 22 X 25. The smoothest side was green and had black writing in various sizes. So, I painted two layers of black spray paint and then 4 layers of white spray paint.

I see LASER etching as interesting but somehow I don’t see it as something I’m going to get into. I guess I’m much more oriented toward functional over decorative objects.

I am not going to give up 3D printing either, but I see a blending of the two. I have already seen thingiverse has a lot of 3D prints for use by people with etchers. I showed one above. I also see some things strictly to be used by etchers. An example is the wall art.

I was looking into getting a Makeblock xTool D1 Laser Engraver

But I am not quite ready just yet. I think it looks like a good unit but seem to be more for Hobby Crafters making little What-evers.

I do enjoy the challenge of getting things to work and tinkering with things to see what I could make, BUT I am going to save my money for awhile and see what the next best thing to come along is.

I have heard that the software that comes with it is limited and that LightBurn is so much better but more expensive, plus at my age I don’t know if I man ready for the challenge of learning another new drawing system.

I think I will wait for a while longer…

Jack

Lightburn has several libraries which are available at different places. One is called Art Library, another is material Library and the third is of course Laser Library. These make it very easy to design and cut/etch material. You can add to your own personal libraries with free pictures off the internet or personal pictures of family member or favorite landscapes onto many materials.

Let me not forget, there are several people making educational videos about Lightburn, or even the etcher you are interested.

After watching a dozen videos and doing some test prints, the tests are to give you a guide as to how much power. I painted a white dinner plate with white pant and let it dry about 12 hours. I then took a picture of my step father and tried to burn it onto the plate for my mom. First step was to place the plate at a certain point on the bed, focus the laser and then see if the size of the print would fit without bumping the plate where it curves up. The height of the laser housing is only about 2mm above the plate to be etched. I then etched the grayscale picture.The white paint helps burn or heat the laser point on the ceramic plate… Diode lasers for hobbyist are not that powerful, even though hotter and hotter ones have recently become available. Mine is a 40W input and 5.5wats output. A newer one is 50 watts with two small lasers focused together and creating 10 watts output. The next step up is CO2 lasers and they start about 40 watts and go up to 100 watts, maybe more. But those start about $2600. The next is fiber and there you start about $10,000 for full refrigerated lasers. Now back to the story. I took acetone to wash the paint off and got a somewhat grayscale picture. My first try and it lacked something to be desired. That is nothing like what the videos show.

Now I did download a bird house pattern to use 1/8 or 1/4 inch plywood. I will try to make some birdhouses and no nails required. Only other item required would be a dowel for the perch and maybe some glue. The fit is supposed to be tight enough to not need glue.

Something else I did do and was satisfied was I took some heavy paper for calling cards and in a desktop publishing program, created a page of calling cards. Had the template for years. I then placed it on the laser bed and laser cut them out with rounded corners and as a hobby, laser engraving which was actually letters cut out of the card. They looked great. I liked the idea of the rounded corners instead of square.