A trick for soldering very narrow traces is to strip the insulation from some small guage wire & wrap it around the soldering tip multiple times, leaving a length of it to form a new soldering tip. Of course, magnification is needed to solder such narrow traces.

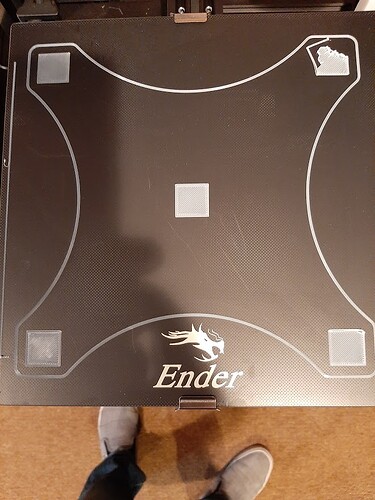

I don’t think I am going to try soldering this one. I like my coffee too much. Beside, it looks like the socket itself is missing a pin. Hopefully, I will be able to get a replacement. In the meantime, it still functions as it is with the stock firmware. I did switch to Jayo filament that I got from amazon. My levelling print is showing this (see attached). Not sure if this means there is warp in the bed. Am I supposed to check for warp with the glass on or the glass off? This was printed at 70c bed and 215c nozzle (the box that the filament came in recommended nozzle temp of 210 to 230 and bed temp of 60 to 80). Thank you.

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“full”,“title”:“newfilament1.jpg”,“data-attachmentid”:9399}[/ATTACH]

I’m still seeing signs of an unlevel bed.

It looks like you need to back off on the tension of the back-right adjustment wheel (turn it clockwise when looking down on it from the top) in order to get the nozzle closer to the bed. I would recommend 1/8 turn at a time.

The front-left looks too close. Turn the adjustment wheel counter-clockwise 1/4 turn.

My own feeling about checking for warp is to check with the bed that will be printed on.

Did you have anything on the SD card other than the update file for the screen? The way I got mine to work was to format the SD card to Fat32 then copied the screen update file to it, put it in the screen SD card slot the powered up, it went through the screen color changes and when done when I booted it had the update.

Gramps…that is exactly the procedure I used. The only variation was that I did not have q 4gb microsd card so I used a 16gb, formatted it for FAT32 and copied that DWIN directory to it and then inserted it into the microSD card slot inside the LCD unit. As I said…no joy and upon closer inspection, I could see that some of the tiny connections were not properly soldered. Too small for me to mess with, though. Thanks.

As a last check of the SD Card slot, you could put a gcode file on it, then see if the filename is listed if you use the LCD to try to print it.

Do you mean I should put a gdcode file on the microSD card and put it into the slot on the backside of the LCD? I didn’t think that slot was used for anything other than updating the LCD firmware. No?

Are you saying you have 2 SD Card slots?

Yes. One on the front left of the machine. The 2nd one is on the backside of the LCD board. You have to remove the back of the LCD case to get to it. That is the one that needs have firmware upgraded first, according to the th3d site instructions for the Marlin firmware. https://support.th3dstudio.com/hc/downloads/unified-2-firmware/creality/creality-ender-3-v2-firmware-lcd-firmware-v4-2-x-board/

Thanks. I wasn’t aware that the V2 printer had this change from the V1.

I just thought of something. 1 issue you might be having is that your SD card m-a-y be too large. It might only be able to handle cards up to 4GB (the maximum addressable memory for a 32 bit processor). If you have a card 4GB or smaller I would try the upgrade again with it.

Thanks. I will see if I can find 4gb card…perhaps lurking in an older Raspberry Pi. Meanwhile, thanks for your levelling tips. I just printed a filament guide pulley and it came out great.

I really appreciate all of your help here. I will report back on whether I can find a 4gb card and whether it will work.

A smaller card will also work. I can’t imagine the LCD files use up more than 100Mb.

The LCD on the v2 doesn’t play nice with Marlin it has it’s own proprietary firmware on it. I changed mine to a 12864 LCD screen for an Ender 3 Pro not color and fancy but it works and you don’t have to flash the firmware everytime you flash Marlin. It’s like a $20 upgrade

Makes one wonder what Creality was thinking…

Thanks Gramps. I did find that suggested on the th3d page with the Marlin upgrade directions. I ordered one yesterday. Seems like maybe Creality got ahead of its ability to keep up with firmware developments. SO, one step forward for the machine firmware and one step back for the LCD display.

BTW, is it recommended to clean the nozzle between each use? If not, is there a recommended interval for that or just wait until it accumulates gunk?

@arniep, I find it’s cheaper to replace nozzles every few months. They’re only around 50 cents each.

Thanks. I wasn’t thinking of the cost as much as whether schmutz on the nozzle being a risk for stringing or even dislodging the print.

It shouldn’t really be a problem if the retraction is set correctly.

BTW, I just noticed that Creality.com has a Marlin firmware upgrade for the E3 V2 dated March 25, 2021 on its download page now. It doesn’t say whether you have to have the LCD firmware upgraded prior to installing this, like it says on the th3d Marlin upgrade page.

I think with the stock v2 LCD you have to do the LCD firmware update each time you update the motherboard. I never had much luck with the Creality firmware other than what came on mine. I’m using Unified2 from TH3D and I like it works fine on my v2 with the 12864 screen. One thing to remember with TH3D’s Unified2 firmware when you change the LCD to the 12864 you compile the firmware as if it’s a Ender3 not and Ender3 v2