I had nothing but problems a month after it arrived November 2022. I bough a pre-assembled one, despite that hub is fully capable of assembling one. So am I, if it weren’t for MS, me not being able to do that anymore, but just to show I know how a printer is constructed. Doing that turned out to be great, as otherwise repairs would have been costly under EU laws, as self-assembly was a big problem for warranties, they made that very clear. The printer is still under warranty, but it came from a reseller. Have to say that if he didn’t intervene, it would not have been fixed the first time.

We had 2 printers before this one, who both became useless after a series of outages. Lesson learned, the Prusa is on a battery. Nothing wrong with our electricity net, it’s designed by me, installed by hub, and legally approved. Belgian electricity laws are very strict.

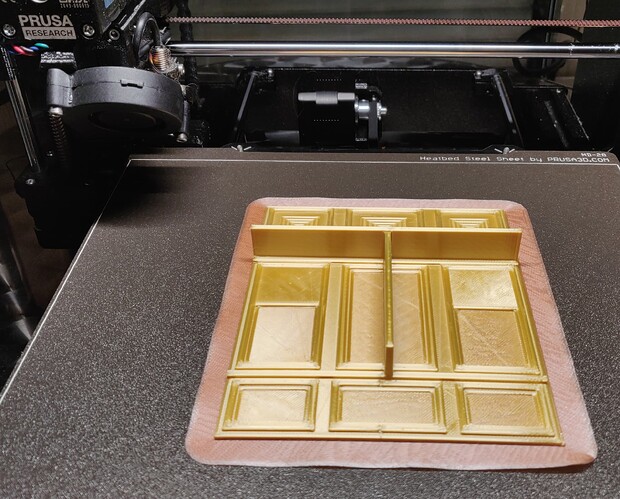

First, the new SuperPinda broke down. I suddenly also had massive blobs all over the place, knocking prints off. It printed all over the place, at irregular heights. They sent a new SuperPinda. It didn’t fix it. They sent another motherboard, it didn’t fix it. It was sent back to them, it was fixed. I have no clue what they did, really, as their report was rather generic. They said I lubed too much, and on places nobody in their right mind would lube, which I didn’t. Yet, when it returned, they themselves overlubed it and I have had to wipe it 3 times in 3 months, as clumps of lube keep gathering in places they shouldn’t. See what I mean, and this on all rods by the way.

They claimed that the SuperPinda was incorrectly installed. We followed their manual and took many pics before and after, to compare to see if it was exactly the same, so what does that say, sigh? They claimed I complained about the vibration and fixed it, yet I never did. I was without a printer for 3.5 months. The first print I did after it returned had a massive clog right from the start, sigh. It was their filament, as I never used black glitter. It got unclogged with a no-clogger, luckily no disassembly needed.

I print miniatures mostly. I use PLA 99% and TPU rarely. I vary colors often and I have many colors to choose from. There is not one brand which prints without problems, but luckily some print with workarounds.

Z dropped 1 mm in height in 1 month. I have no clue if that’s normal.

The build plate hates Winkle PLA, which was my favourite filament till now. Previous printers had no issue with holding it onto the build plate. Different textures sheets obviously. Fiddling with temps and cooling didn’t help. Eryone and Kexcelled attach better, but still not perfect. I have tried other brands and it all was a flop. I am allergic to glue and hairspray, so I prefer not to use it. I do can stand tape, so taping the raft or brim is how I am now printing the last of the filaments which it doesn’t adhere. I can never print without a brim or raft. I have to keep an eye on the first layer constantly and check often. Printbed gets wiped clan daily. I have a filament dryer, which I always use on each roll.

It always starts to detach on the left, as you can see with this opaque PLA.

At 17 cm high, it gets serious layer shifts. I got advice to increase z-hop for those prints, which I will try next time I make a large print.

I still have blobs on the first layer, which knock the prints off. When blobs happen higher up in the print, I can hear the printer do a “crash detect” and go and clip the blob off by pausing the print. I had massive blobs before it was shipped back, it has improved a lot, but it’s annoying still.

I often get complete unreadable text on my screen. It lasts 2 secs, I have not been able to take a pic of it yet.

It started a print with this ultrawide blobby lines, yet the print after was perfect. Layer height was supposed to be 0.2 at first layer. I have no idea what that is.

It should be able to print at 90 speed, but anything over 75 gives me ridges, no matter how I adjust temps and cooling. This was a simple flat piece, so it should have handled 90 well.

I have to do a first layer calibration on a regular basis. It only works for a 14 days at best, then it’s way off again. 2 corner of the small slab had a small blob which got smeared out, but otherwise is the best result I can get.

First layer calibration often does not even work, as the first print after is off, despite a decent calibration.

And then, next print after, same gcode, same filament, it prints …

I had a thermal anomaly. Next print, same gcode, no problem. Pic taken after the print was stopped, because the PLA stank. Notice how it changed the bed texture to smooth as well, this happens now and then. I never print on my smooth bed anymore, as all prints detach on it.

I discovered that using Cura instead of Prusa makes adhesion much better though. Their first layer construction is different. Yet, I should be able to use PrusaSlicer, right?

I envy people who can print on their Prusa without blinking an eye. Mine is a lemon. I am currently gathering enough data to contact their helpdesk again. It has been suggested that I should swap it. Can I still? This is a disaster lemon for me. Hub, who is an IT’er (I used to be), says he waould have thrown it out the door months ago and praises me for being so tenacious. Yes, but I have cried more than once, seriously, and my grey hairs have increased.