I am beginning my review of the Flashforge Creator 2. It is a massive device built like a safe and about as heavy. I expect the relatively small build volume combined with a very heavy and rigid frame will result in high-quality prints. I think @Ender5r may be correct. The Flashforge is designed for people who want an appliance. The setup wizard built into the firmware is much better than the user guide and quite clear.

The printer was 95% assembled with a couple of minor items requiring a hex wrench.

When I checked the dual extruder calibration my printer was already perfect. Flashforge claims all devices are tested at the factory and my device listed 2 hours of print time when I turned it on and checked the statistics provided via the front menu.

The color touch screen is very nice and easy to use.

I am printing my first print from the full-size SDcard, which is estimated at over four hours. It is a two-color print, and it had an ooze wall around the print. I have not used a wall to reduce oozing, and I am very interested to see how well this works. I do expect it significantly extends the print time.

Just visually, nothing scientific, the printer seems quite fast. Flashforge may be able to ramp up the acceleration and jerk limits because the printer is quite heavy.

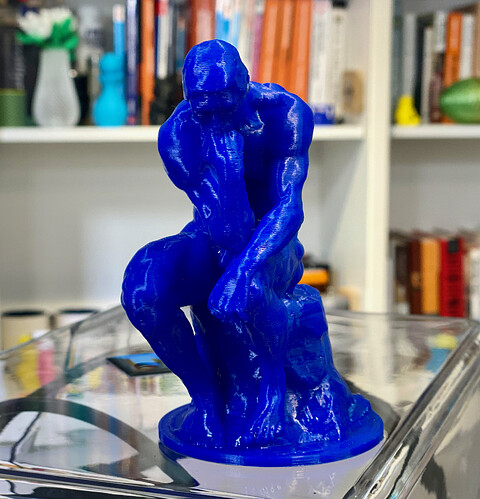

One disadvantage of an ooze wall is it makes it hard to see anything. From the side you just see a solid object:

[ATTACH=JSON]{“alt”:“Click image for larger version Name: IMG_5815.jpg Views: 0 Size: 993.8 KB ID: 10487”,“data-align”:“none”,“data-attachmentid”:“10487”,“data-size”:“custom”,“height”:“288”,“title”:“IMG_5815.jpg”,“width”:“512”}[/ATTACH]

There are very nice lights inside the printer (which is fully enclosed with a clear area in the door), and the blue print surface makes everything look blue. This video is at actual speed. I did not speed it up or slow it down. The printer is not quite and clearly, does not have the most recent stepper motor drivers.

Here is a video from the top:

[video=youtube_share;nAMPuFQaDT4]FlashForge Creator Ooze Wall - YouTube

It will take me a few days to print enough samples for a reasonable review, so expect a video at the end of this week or early next week.

Irv