Yes, that title is a mouthful.

3d printer speed is important to me as I often need to print multiple models for a particular video and I rarely have as much time as I would like.

Based on personal experience my fastest 3d printer is my Prusa i3 Mk3. Unfortunately, that printer is now at my son’s house, in another state, as I was running out of room and I wanted to have a printer to use with my grandsons. Back at the MakeWithTech lab, I have lots of printers to choose from and the faster one is my Monoprice Ultimate 2. Unfortunately, the Ultimate 2 has a relatively modest build volume.

I noticed a couple of common characteristics with the 3d printers I own that run the fastest reliably. They have rigid frames (the Ultimate 2 is fully enclosed) and they use direct extrusion. Unfortunately, the direct extruders on both of these printers are hard to work on. I was looking for an alternative.

Over the past 2 years, I have completed many upgrades to my Ender 5 that I purchased from Creality the day it was listed on their website. It has a SeeMeCNC EZR Struder Bowden style extruder I highly recommend, Capricorn Tubing, a Th3d EZABL, a Micro Swiss all-metal hot end, and a 32 bit Marlin 2 Th3d EZBoard Lite controller. Plus I have added a couple of 3d printed additions to further strengthen the frame. But since it has not been the shiniest printer in the lab the last 12 months it has seen limited use. It is time for me to take another look.

6 months ago I purchased a Micro Swiss Direct Drive Extruder for the Ender 5 and put it in a drawer. I came across it a couple of days ago while I was spending hours with my Artist-D Pro and thought maybe the Ender 5 with a Direct Drive Extruder could become my new extra reliable, high speed, day-to-day 3d printer.

I began working on this video with a timing test. Using Cura 4.11 and the standard Ender 5 profile that comes with Cura I did a test print. Cura estimated a print time of 2 hours and 1 minute. The actual print time was 2 hours and 4 minutes. This was great news because I could limit the number of test prints and use Cura to estimate the performance upgrades I would see with a direct extruder.

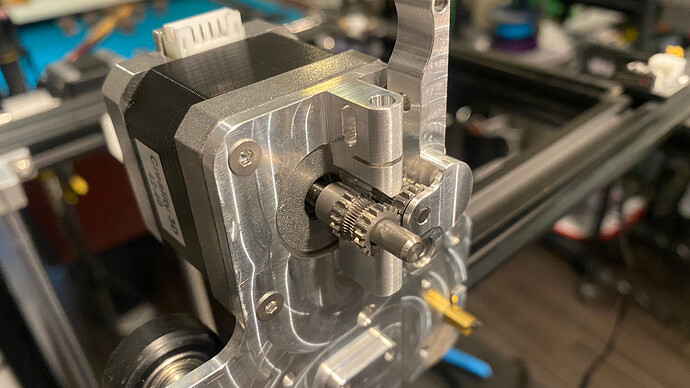

This morning I installed the new Micro Swiss Direct Extruder and much like their all-metal hot-end it is very well manufactured. What I didn’t realize, but should have because it is right on the box, is that I was also upgrading to a very robust dual gear extruder setup.

Here are some pictures while I do some more testing and film the video.

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“custom”,“height”:“338”,“title”:“IMG_6577.jpeg”,“width”:“600”,“data-attachmentid”:11488}[/ATTACH]

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“custom”,“height”:“338”,“title”:“IMG_6578.jpeg”,“width”:“600”,“data-attachmentid”:11489}[/ATTACH]

[ATTACH=JSON]{“data-align”:“none”,“data-size”:“custom”,“height”:“338”,“title”:“IMG_6579.jpeg”,“width”:“600”,“data-attachmentid”:11490}[/ATTACH]

The short length of Capricorn tubing shown in the video stops at the top of the heat break and does not enter the hot area.

The video should be out this week.